Copper mining is the process of extracting copper from its ores, which is essential for supplying a metal widely used in electrical wiring, infrastructure, and renewable energy technologies. It involves both surface and underground mining techniques depending on the location and the size of the deposit. Copper’s high conductivity and corrosion resistance make it a critical resource in modern industry and green technology.

The global demand for copper continues to grow, driven by the shift towards cleaner energy and expanding electrical infrastructure. Major producers like Chile and Canada lead production, with Canada contributing significantly through mines in British Columbia and Ontario. Mining companies are exploring new deposits to meet future needs amid concerns about supply shortages.

Environmental and economic factors shape copper mining practices worldwide. Advances in extraction methods aim to balance production with minimizing ecological impact. Understanding the mining process and global market dynamics offers insight into copper’s pivotal role in today’s economy.

Overview of Copper Mining

Copper mining involves extracting copper ore from the earth and processing it into usable metal. The distribution of copper mines, the types of copper ores mined, and the leading producers shape the industry. Understanding these aspects clarifies the global landscape of copper supply.

Global Distribution of Copper Mines

Copper mines are distributed across all inhabited continents, with concentrations in regions rich in porphyry copper deposits. Key mining areas include South America, North America, Africa, and Asia.

Chile stands as the largest copper mining region, hosting significant open-pit mines like Escondida. The United States has prominent mines in Arizona and New Mexico. Peru is another leading producer with multiple open-pit and underground operations.

Africa features important mines in the Democratic Republic of Congo and Zambia. Asia’s production centers around China and Indonesia. The distribution reflects geological formations and availability of copper-rich ore bodies.

Types of Copper Ore

Copper ores are primarily categorized into sulfide and oxide ores, each requiring different extraction techniques.

Sulfide ores are the most common and include minerals like chalcopyrite, bornite, and chalcocite. They are typically processed through flotation followed by smelting and refining.

Oxide ores contain minerals such as malachite and azurite. These ores are softer and usually processed by leaching and solvent extraction.

The type of ore influences mining methods and processing technology, affecting cost and environmental impact.

Major Copper Producers

Leading copper-producing countries dominate global output through large-scale mining operations and extensive refining capacities.

| Country | Approximate Share of Global Production (%) | Key Mines |

| Chile | 28 | Escondida, Collahuasi |

| Peru | 12 | Cerro Verde, Antamina |

| China | 9 | Dexing, Tongling |

| United States | 7 | Morenci, Bingham Canyon |

| Congo (DRC) | 6 | Tenke Fungurume |

Chile’s dominance is supported by both large deposits and advanced infrastructure. Peru and China follow with significant output. The United States maintains substantial reserves, while the DRC’s production is rapidly growing due to high-grade deposits.

These countries control the majority of copper supply, impacting global markets and pricing.

Copper Mining Processes

Copper mining involves multiple steps that transform low-grade ore into high-purity copper. These steps include locating deposits, extracting ore, processing it to separate copper, and managing the environmental impacts associated with mining.

Exploration and Extraction Techniques

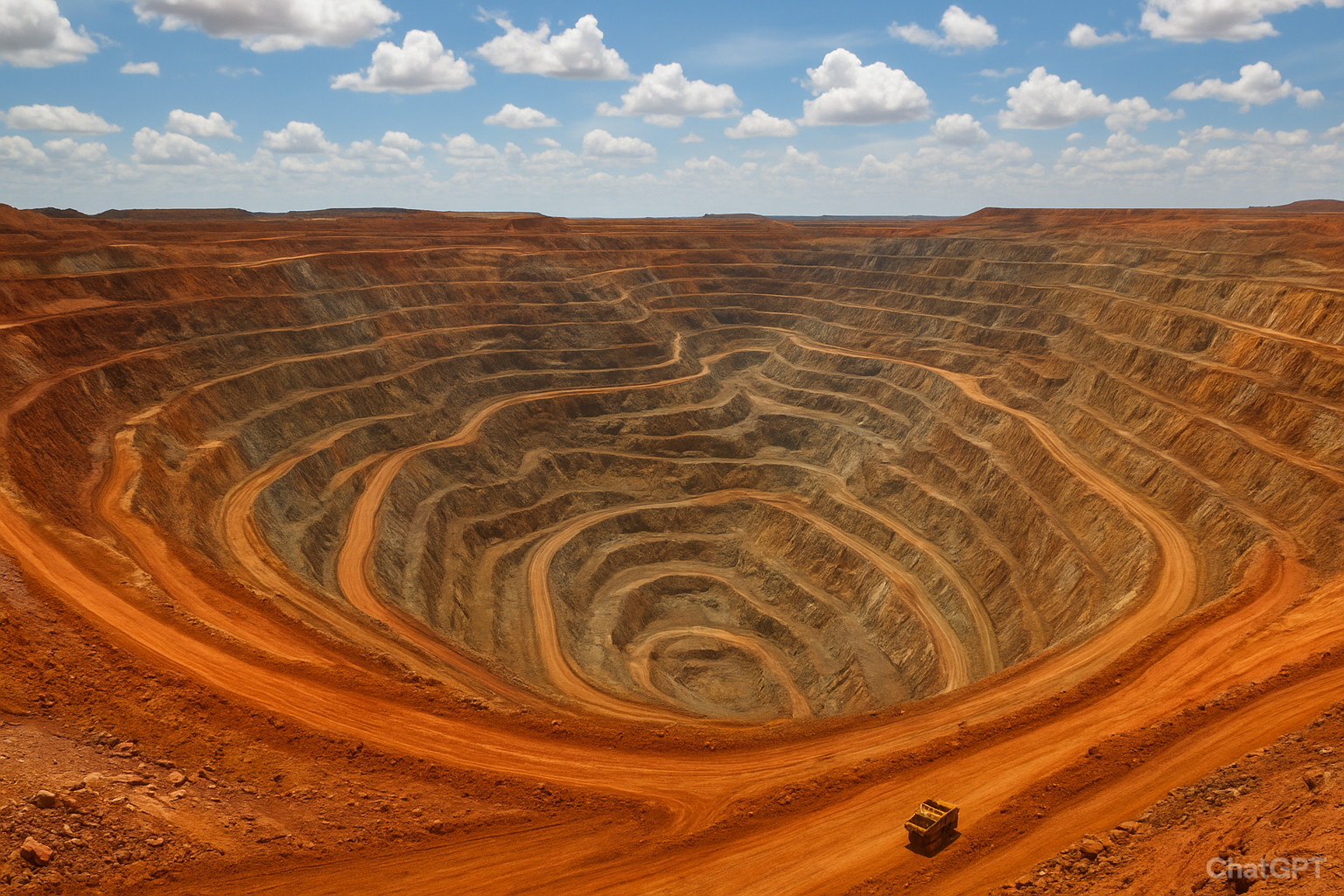

Exploration begins with geological surveys and drilling to identify copper deposits. Once a deposit is confirmed, the choice between surface (open-pit) mining and underground mining depends on ore depth and deposit accessibility.

Open-pit mining removes vast amounts of soil and rock to access shallow ore bodies. It is cost-effective and dominant in large, near-surface deposits. Underground mining targets deeper deposits via tunnels. It is more expensive but minimizes surface disruption.

The typical copper content in ore is less than 1%, necessitating large-scale extraction. Mining processes aim to maximize ore recovery while considering safety and operational efficiency.

Ore Processing Methods

Copper ore processing varies by ore type: oxide or sulfide. Oxide ores undergo hydrometallurgy, involving leaching and solvent extraction to isolate copper. Sulfide ores require pyrometallurgy, where ore is crushed, concentrated by flotation, and smelted.

Key steps include:

These processes concentrate copper and remove impurities. Quality control ensures the final product meets industrial standards.

Environmental Impact and Sustainability

Copper mining significantly alters landscapes and ecosystems. Tailings, waste rock, and chemical use pose contamination risks. Modern operations implement measures such as water recycling, dust control, and proper waste management.

Sustainability efforts focus on reducing environmental footprints through:

Regulatory frameworks require continuous environmental impact assessments to balance resource extraction with ecological protection.