When an HVAC system fails, the disruption is immediate and visible. Offices overheat, residential blocks lose comfort, and maintenance teams scramble for quick fixes. Yet in many cases, the problem traces back to a small, easily overlooked component: the capacitor.

Across the UK property sector, there’s growing awareness that not all capacitors are created equal. This has led many landlords and facilities managers to take a closer look at UL Approved HVAC Capacitors in canada—particularly those manufactured and distributed within Canada’s tightly regulated electrical market.

UL approval isn’t just a label. It’s a signal that a component has been tested to withstand electrical stress, heat, and long-term use. For UK buildings operating under increasing compliance and insurance scrutiny, that assurance matters.

UL (Underwriters Laboratories) certification is one of the most widely recognised safety benchmarks in the electrical world. A UL-approved HVAC capacitor has been independently tested for electrical safety, fire resistance, and performance consistency.

In practical terms, this means the capacitor is far less likely to:

For UK property owners, especially those managing multi-occupancy buildings, these risks are not theoretical. A single electrical fault can trigger tenant complaints, insurance questions, and unplanned downtime.

That’s why UL Approved HVAC Capacitors in canada are often specified for systems where reliability and safety carry equal weight.

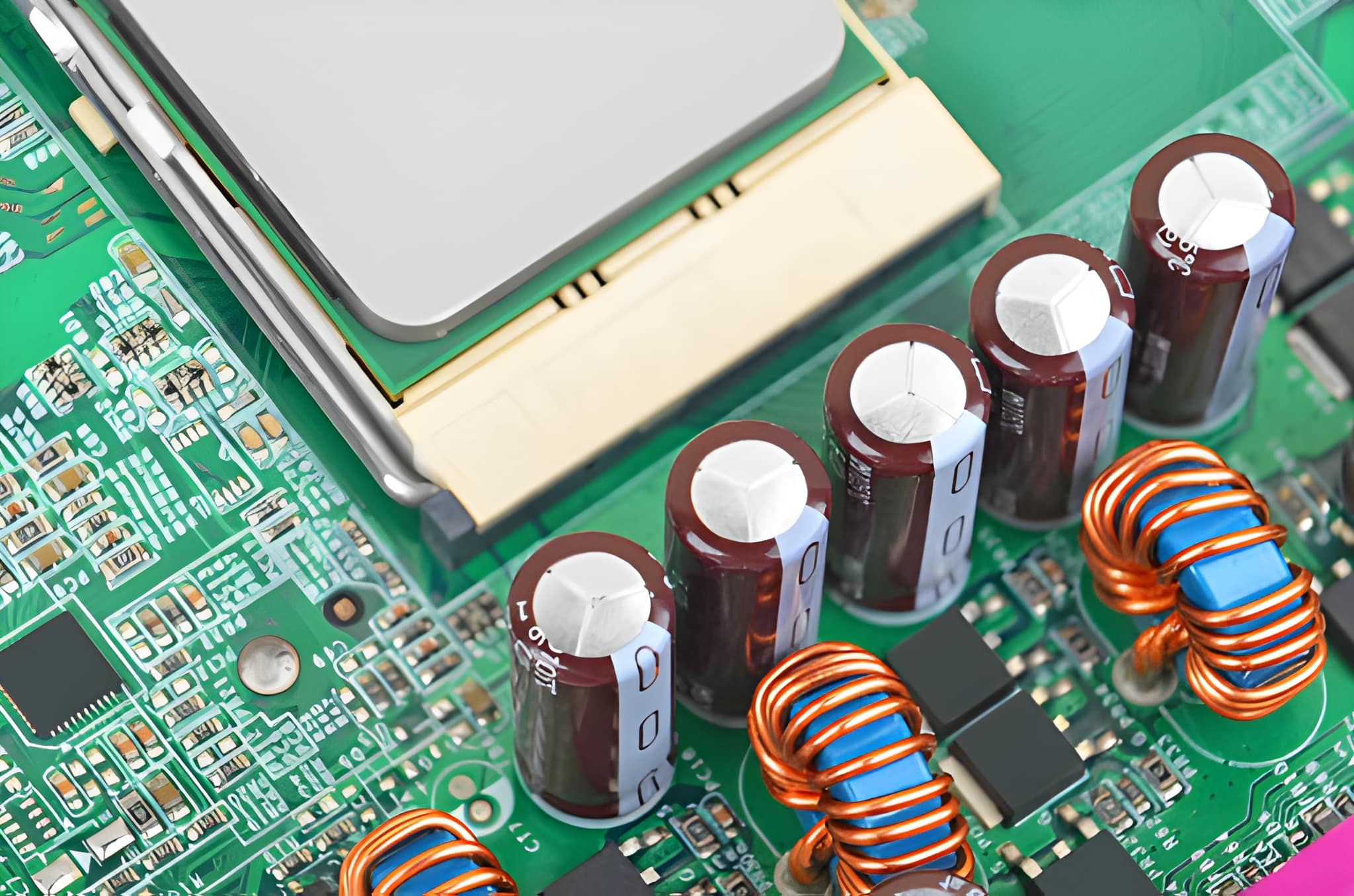

Canada’s HVAC and electrical manufacturing sector operates under demanding conditions. Extreme cold, long run times, and commercial-scale installations shape how components are designed and tested.

Capacitors manufactured for this environment are typically built with:

When UK buyers source through experienced distributors such as en-trade.ca, they’re not just purchasing a component—they’re accessing a supply chain built around safety documentation, traceability, and long-term reliability.

Consider a care home or hospital-adjacent property in the UK. HVAC systems in these environments operate almost continuously, and failures aren’t just inconvenient—they can become serious operational issues.

In one such upgrade project, repeated capacitor failures were traced to non-certified components that degraded under constant heat. Replacing them with UL-approved capacitors sourced from Canadian suppliers stabilised the system almost immediately. Starts became smoother, internal temperatures dropped, and maintenance call-outs reduced noticeably.

This is where UL Approved HVAC Capacitors in canada quietly prove their value—not through flashy performance, but through consistency and peace of mind.

Certification alone isn’t enough. Correct specification is what turns a good component into a reliable solution.

Always match microfarad and voltage ratings precisely. Over- or under-sizing a capacitor shortens lifespan, regardless of certification.

Systems in flats, hotels, and commercial buildings cycle far more often than domestic units. Choose capacitors designed for frequent starts and elevated ambient temperatures.

UL approval simplifies compliance, but only if documentation is available. Working with knowledgeable suppliers like en-trade.ca ensures access to datasheets and certification records when insurers or auditors ask.

UK property owners face a tightening landscape:

In this environment, cutting corners on components rarely pays off. UL-approved capacitors reduce the likelihood of electrical faults, improve system stability, and support a more professional maintenance strategy.

The growing interest in UL Approved HVAC Capacitors in canada reflects a broader shift in the UK market: moving away from reactive repairs and towards components that quietly reduce risk.

They are HVAC capacitors that meet UL safety and performance standards and are manufactured or supplied within the Canadian electrical market.

Yes. When specified correctly for UK voltage and system requirements, they integrate seamlessly into British HVAC installations.

In many commercial applications, they demonstrate longer service life due to stricter testing and higher material quality.

For most commercial and multi-occupancy properties, the reduced failure risk and improved safety justify the modest price difference.

While requirements vary, recognised safety certifications often support smoother insurance assessments and risk reviews.